RCD Testing

Voltec Maintenance is Your Trusted Electrical Testing Services, RCD Test Tags, RCD Safety Switch Testing and Leakage Current Testing Service Business in Townsville and North Queensland

Voltec Maintenance is a local business based out of Townsville, specialising in preventative electrical testing and maintenance. One of the four main things we do is conduct RCD electrical testing in Townsville.

What is a Residual Current Device Testing, RCD, & RCD Test Tags?

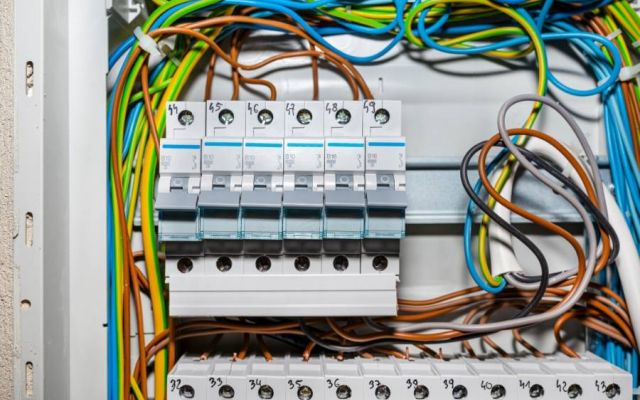

An RCD (Residual Current Device) is a sensitive safety device that switches off electricity automatically if there is a fault. They are also commonly referred to as a Safety Switch. RCDs are in the switchboard and their function is to protect circuits, by tripping power in the event of earth leakage or equipment failure. It continuously monitors the electric current flowing through the circuits it is used to protect.

Having RCDS will prevent electrocution from being fatal. It is vital to the safety of your workplace that your RCD safety switch testing is conducted on a regular basis as they can fail and do have to be replaced from time to time. Failure to replace RCD's can result in a potentially fatal situation. This highlights the importance of RCD safety switch testing, to prevent electrical faults where electricity leaks from the circuit (leakage current testing).

There are 3 main types of RCD’s

- Fixed RCD’s – These are housed in a fuse box and protect a single circuit, or group of circuits. It protects all the wiring and the sockets on a circuit, and any connected appliances, providing the highest level of protection.

- Socket-Outlet RCD’s - This type of RCD only provides protection to the equipment plugged in to this special outlet and the person using that equipment.

- Portable RCD’s – These are very similar to socket RCD’s but they can also be moved from socket to socket as needed. They only provide protection to the equipment plugged in to that socket and the person using it.

All these RCD’s require regular electrical testing to ensure they do not exceed their maximum allowable earth leakage current and are safe to use.

Does your workplace need RCD test tags? Contact us today for a free quote. Learn more about our Test & Tag services, Fire protection services, or Emergency Exit Light Testing services.

Electrical Testing and RCD Test Tags Standards

In Australia, RCD test tags and testing must meet a set standard. This is the AS/NZS 3760:2010 in-service safety inspection and testing of electrical equipment. Once leakage current testing has been conducted, the electrician will place RCD test tags on your equipment to show it has met the electrical testing standards and the due date for the next test. Your device must meet the RCD test tags requirements to ensure that it will respond in a fault situation. If it fails, the test (maximum allowable earth leakage current) it will be removed from service and replaced or repaired.

The Maximum Allowable Earth Leakage Current and Leakage Current Testing

RCDs are designed to quickly disconnect a circuit when it detects that the electric current is not balanced between the supply and return conductors of a circuit. Any difference between the currents in these conductors signifies that there is a leakage current, therefore creating a shock hazard. Hence, the importance of leakage current testing and maximum allowable earth leakage current standards. The central protective measure for electrical safety is good insulation. It ensures that no one touches any live conductors and that a short circuit does not occur. Leakage current testing will tell you all about the quality and safety of the insulation. This test is conducted during actual use of the product and determines if the current leakage is too high from the insulation to the housing. It is both a safety and functional test.

The maximum allowable earth leakage current can vary for each piece of electrical equipment, depending on its use and construction, so leakage current testing should always be done by experienced and trained electricians.

Leakage Current Testing for High-Voltage Circuits

For high voltage circuits, regulation 5.24(2) requires the earth leakage protection device to operate at the maximum allowable earth leakage current not exceeding 2 A. This must be achieved in the context of safe step and touch voltage limits.

Leakage Current Testing for Low-Voltage Circuits

For low voltage circuits, regulation 5.24(2) requires the earth leakage protection device to operate at the maximum allowable earth leakage current not exceeding 1 A. This must be achieved in the context of safe touch voltage limits.

Contact us today for a free quote on leakage current testing.

RCD Testing Service Reports After Testing

Our licensed electricians at Voltec Maintenance meticulously test each RCD using advanced load and trip test equipment to ensure precise readings. After testing, we provide detailed reports indicating pass or fail status. If any defects are found, we promptly recommend repairs, replacements, or upgrades to maintain safety compliance. This ensures a streamlined auditing process and freedom from worry.

What Types of RCD Safety Switch Testing is Performed?

Load Test

A load test can be performed on most power circuits by a technician with a Restricted Electrical Licence. This test measures the power consumption of the equipment when in use. A load test provides a good indication of the equipment’s operating condition. The technician will utilise an RCD tester by plugging it into a power point, tripping the circuit and recording the result. The technician will have to go back and forward to the switchboard to turn the RCD back on between testing 0 and 180 degrees. It is important that the client understands this test is not only testing the RCD, but also the circuit itself. This is a very thorough test if performed correctly and identifies if the RCD and circuit performs effectively. Furthermore, a load testing regime performed on your site will also include the identification of safe Power Points. This is an essential component of RCD safety switch testing.

Injection Test

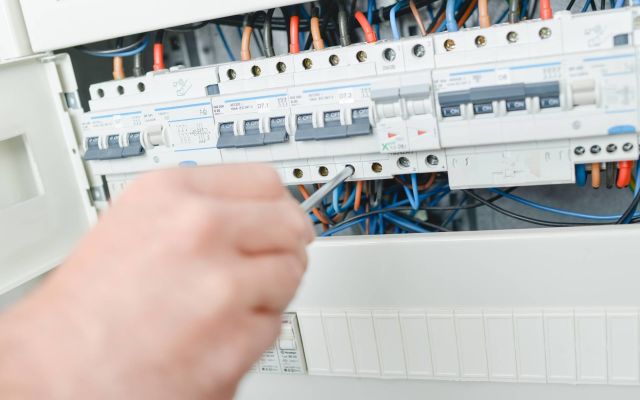

This electrical testing is performed by a qualified electrician by opening the switchboard and tripping each individual circuit. While doing this, the electrician notes down the specific figures at which the circuit trips at both 180 and 0 degrees. The result of this test per circuit is both results added together and divided by two. For example, DB1 Cb32 tripped at 18 & 31 would have a result of 25. It is important that these results are accurately logged and kept for historical data as RCD's trending towards failing over 300 can be identified and replaced, before they fail and result in a potentially fatal situation. A benefit of injection testing will be the real testing of lighting and fixed power circuits. Therefore, it is important to have a qualified electrician perform your RCD safety switch testing.

Push Button Test

A push button Test is conducted by pressing the button located on the RCD which in turn trips the RCD. The functionality of this RCD is proven by the RCD successfully tripping with the pushing of this button. It is important all push button tests are accurately reported pertaining the individual Switchboard and Circuit Breaker. A push button test is not a completely reliable assessment that the RCD is functioning correctly, therefore it is important that regular electrical testing is completed by qualified electricians. A push button test should be completed at minimum 3 monthly intervals.

Portable Load Test

This test is commonly conducted on portable appliances that contain an RCD. It is important to isolate this test, so your site is not affected by the trip in the situation that the RCD does not work. The equipment is inspected visually, followed by verification of earthing (grounding) continuity, and the quality of insulation between the current carrying parts, and any exposed metal that may be touched is tested. Most portable items containing RCD's will need electrical testing done at more frequent intervals.

Portable Push Button Test

This test is conducted by plugging the portable appliance into power and testing the functionality of the RCD by pressing the push button. This test is most conducted on power boards that contain RCD's. This quick and simple test is commonly used with portable RCDs and should be performed daily or before each time you use the equipment – whichever is the longer. However, it is not particularly accurate and should never be relied on as a reliable assessment of the equipment working correctly.

Want more information about electrical testing? contact us today for a free quote. Learn more about our Test & Tag services, Fire protection services, or Emergency Exit Light Testing services.

Intervals of RCD Electrical Testing

Fixed RCD Testing

- Fixed RCD Testing QLD

- Push Button testing to be conducted at 6 monthly intervals

- Load or Injection testing to be conducted at 12 monthly intervals

- Portable RCD Testing

- Load Testing to be conducted at 12 monthly intervals

- Push Button Test to be conducted by user prior to use

Portable RCD Testing

- Load Testing to be conducted at 12 monthly intervals

- Push Button Test to be conducted by user prior to use

The Voltec Maintenance Difference

Our reporting system is proven and tested. We will ensure that you have always reporting in your hands. No tricks or games like other companies who store your data online so they can quickly pull it in case you leave as a customer. Each switchboard is documented by way of a photo. Which will be included in the excel file as demonstrated below. The results will then be specific down to each individual circuit breaker. As time goes on, new results will be added, and historical results will be kept. Identification of trending RCD's will be communicated and displayed on the sheet. As we complete the electrical testing or RCD safety switch testing, RCD test tags will be added to ensure compliance and make it easy for you to see what has been completed and when.

Are you a local business looking for RCD test tags services? Contact us today to get a quote. Learn more about our Test & Tag services, Fire protection services, or Emergency Exit Light Testing services.

Get a Free Quote for Your RCD Safety Switch Testing Services.

Call us today to get free expert advice or a no-obligation quote. We believe in doing the job the right way, not the easy way.

In addition to general Electrical Testing and RCD Test Tags, we are specialised in commercial electrical services. Are you looking for a commercial electrician? Learn more about our Fire Equipment Testing, Electrical Test and Tag, or Emergency Light Testing.