Why Electrical Thermal Imaging is a Must-Have for Preventive Maintenance Schedules?

Electrical faults can build silently over time, posing serious risks to operations, equipment, and safety. While traditional inspections rely on visible signs, they often miss underlying issues—until it’s too late. That’s where electrical thermal imaging becomes a game-changer for preventive maintenance.

This non-invasive, highly accurate technology allows facility managers and business owners to identify electrical issues before they lead to costly downtime or dangerous failures. Here's why integrating Thermographic Testing into your preventive maintenance schedule is not just smart—it’s essential.

1. Detect Invisible Problems Before They Escalate

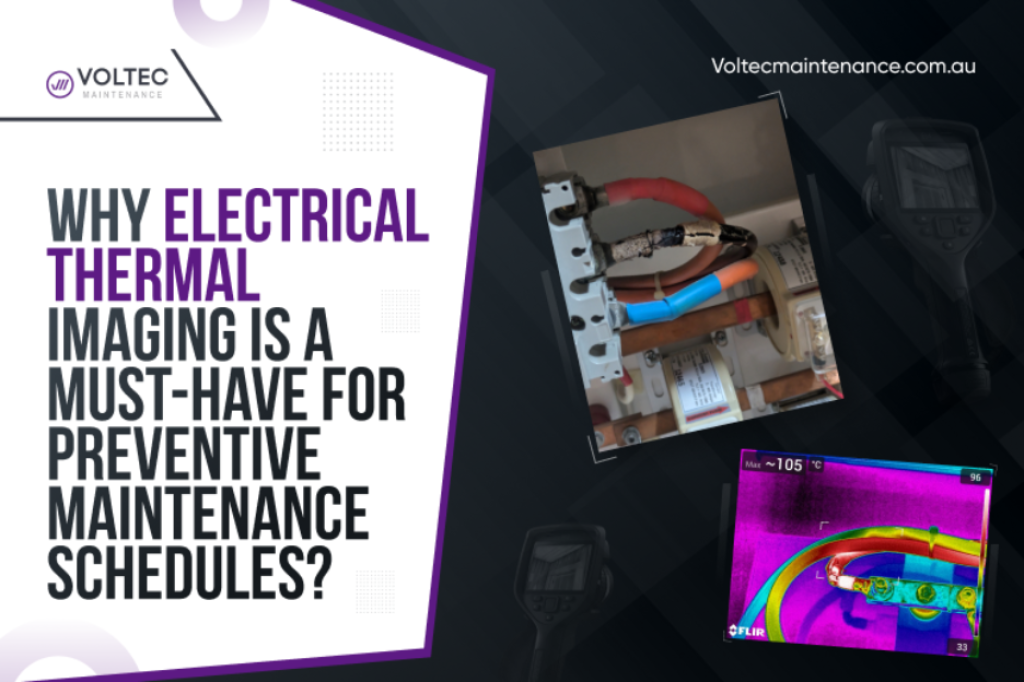

Thermal imaging cameras identify abnormal heat patterns in electrical systems—often the first sign of an impending fault. These temperature variations reveal problems like overloaded circuits, loose connections, phase imbalances, and failing components, long before physical symptoms appear. Catching these issues early prevents fires, malfunctions, and business interruptions.

2. Enhance Safety for Staff and Property

Undetected electrical faults are a leading cause of workplace fires and serious incidents. With thermal imaging, potential hazards are identified without direct contact or shutdowns, keeping inspection teams safe and systems operational. By prioritising thermal inspections, businesses show proactive commitment to workplace health and safety.

3. Minimise Downtime and Avoid Emergency Repairs

Unexpected electrical failures can halt operations, delay services, and damage sensitive equipment. Thermal imaging done by Commercial Industrial Electricians helps facilities schedule targeted maintenance during planned downtime instead of reacting to emergencies. This approach reduces disruption and allows for cost-effective repairs before problems become crises.

4. Support Insurance and Compliance Requirements

More insurers and regulators are encouraging or even requiring documented evidence of ongoing preventive maintenance. Thermal imaging reports offer concrete, time-stamped proof that your electrical systems are routinely inspected and maintained. These records can support insurance claims, reduce liability, and ensure regulatory compliance.

5. Cost-Effective, Non-Invasive, and Fast

Unlike manual inspections, Electrical Thermal Imaging doesn’t require shutting down equipment or disassembling components. The process is quick, doesn’t interrupt daily operations, and covers large areas efficiently. It’s a cost-effective way to monitor complex systems with minimal impact on productivity.

6. Actionable Insights with Visual Proof

Voltec’s thermal imaging services go beyond basic scans. We provide detailed reports featuring clear thermal photos, temperature readings, fault locations, and actionable recommendations. This visual clarity helps decision-makers understand what needs fixing and why—without guesswork.

Frequently Asked Questions

Choose Voltec’s Expert Solutions

Voltec Maintenance delivers advanced Thermal Imaging Services tailored for commercial and industrial clients across Townsville. Led by a Level 2 qualified technician—an expertise that sets us apart from many in the area who hold only Level 1 qualifications—our team uses state-of-the-art technology and detailed reporting to help you stay ahead of potential failures, reduce risks, and protect your business assets.

If your preventive maintenance plan doesn’t include thermal imaging—now is the time to upgrade.

Read Other Blogs

-

7 Fire Protection Services Every Business Needs (And Why They Matter)

7 Fire Protection Services Every Business Needs (And Why They Matter) -

Emergency Exit Light Maintenance Checklist for Industrial, Retail & Office Facilities

Emergency Exit Light Maintenance Checklist for Industrial, Retail & Office Facilities -

2026 Business Fire Safety Checklist: Smoke Alarm Essentials

2026 Business Fire Safety Checklist: Smoke Alarm Essentials -

5 Questions That Reveal Your Fire Safety Weak Spots

5 Questions That Reveal Your Fire Safety Weak Spots -

The Importance of Test & Tag for Hotels, Restaurants & Cafes

The Importance of Test & Tag for Hotels, Restaurants & Cafes -

5 Checks to Know If Your Exit Lights Would Work During an Emergency

5 Checks to Know If Your Exit Lights Would Work During an Emergency -

How Professional Smoke Alarm Servicing Minimises Workplace Disruptions?

How Professional Smoke Alarm Servicing Minimises Workplace Disruptions? -

How Routine RCD Testing Prevents Downtime and Compliance Issues?

How Routine RCD Testing Prevents Downtime and Compliance Issues? -

The Role of Smoke-Alarm Systems for Business Continuity in Healthcare Facilities

The Role of Smoke-Alarm Systems for Business Continuity in Healthcare Facilities -

How Poorly Maintained Exit Lights Undermine Emergency Evacuation Efficiency?

How Poorly Maintained Exit Lights Undermine Emergency Evacuation Efficiency?