How Expert Thermal Imaging Services Can Keep Businesses Running In Hostile Environments?

Most businesses or industries, such as manufacturing, mining, heavy logistics, and chemical processing, operate in hostile environments like high temperatures, dust, moisture, or corrosive materials. These conditions place immense stress on electrical equipment, machinery, and infrastructure. Unexpected failures not only cause costly downtime but can also pose serious safety risks.

This is where expert thermal imaging services become indispensable. By hiring experts for Thermal Imaging Service to detect heat anomalies and hidden electrical faults early, businesses can maintain operations safely and efficiently, even in the harshest conditions.

1. Early Detection of Electrical and Mechanical Issues

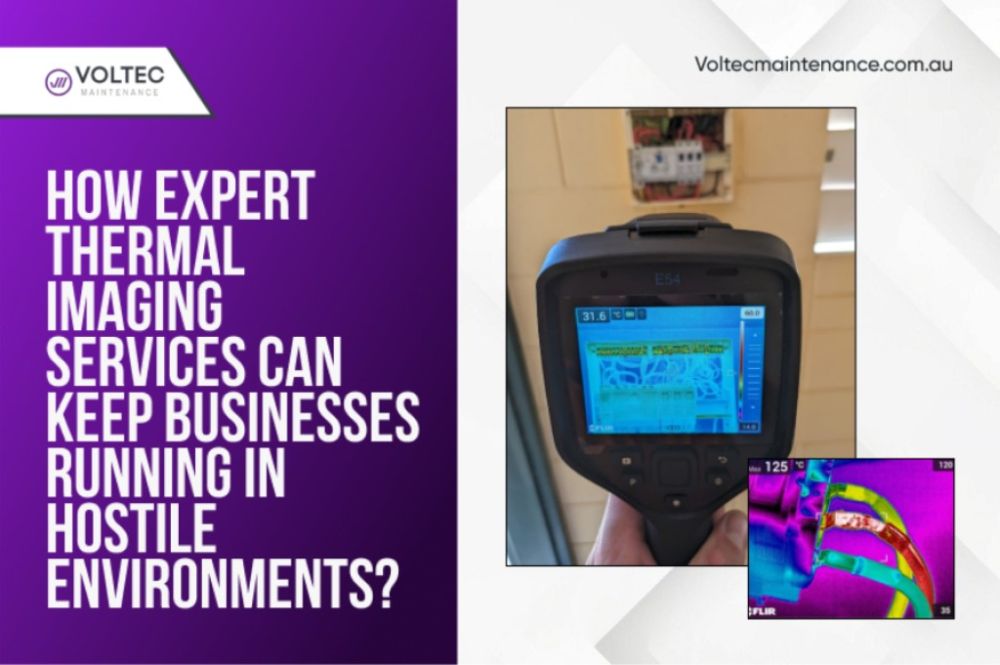

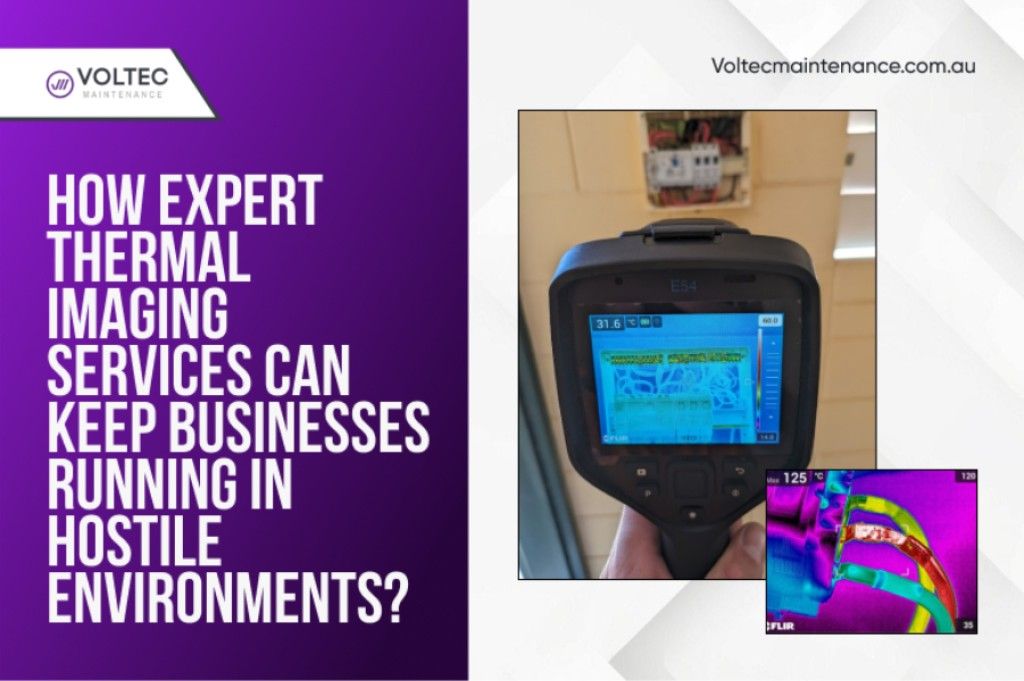

Thermal imaging, or infrared scanning, identifies hot spots and abnormal temperature fluctuations in electrical panels, motors, transformers, and other equipment before they escalate into failures. In hostile environments, these issues can develop quickly due to dust accumulation, high humidity, or extreme temperatures. Early detection allows maintenance teams to intervene before breakdowns occur, ensuring continuity in production or service delivery.

2. Minimising Downtime and Operational Disruptions

Unplanned downtime in critical operations can result in significant financial losses. By scheduling regular Electrical Thermal Imaging inspections, businesses gain a predictive maintenance tool that reduces emergency repairs and unexpected shutdowns. Instead of waiting for a visible problem, companies can plan interventions strategically, keeping equipment running smoothly while protecting employee safety.

3. Enhancing Safety in High-Risk Settings

Hostile environments often mean elevated risks for fire, electrical shock, or equipment failure. Thermal imaging detects overheating cables, failing circuits, and worn components that could trigger hazardous situations. By identifying these risks early, businesses protect staff, prevent injuries, and reduce liability.

4. Comprehensive Data for Better Decision-Making

Expert thermal imaging services provide detailed reports with visual heat maps, temperature readings, and recommended corrective actions. This data helps facility managers make informed decisions about equipment replacement, maintenance schedules, and operational adjustments. Such actionable insights enhance overall efficiency while extending equipment lifespan.

5. Compliance and Risk Management

For businesses in regulated industries, maintaining compliance with safety and operational standards is critical. Thermal imaging supports audits, insurance requirements, and risk management strategies by documenting equipment conditions and demonstrating proactive maintenance. Companies that invest in regular Thermal Imaging Switchboards inspections showcase a commitment to safety and reliability.

Things you May Want to Know

Choose Voltec’s Expert Solutions

At Voltec Maintenance, our thermal imaging services are tailored for businesses operating in challenging environments. We combine advanced technology, skilled technicians, and detailed reporting to help you prevent equipment failure, protect staff, and ensure business continuity. From industrial sites to complex commercial facilities, Voltec provides the expertise needed to keep operations running safely and efficiently.

Invest in reliability and safety—choose Voltec’s Commercial Industrial Electrician for expert thermal imaging services today.

Read Other Blogs

-

5 Questions That Reveal Your Fire Safety Weak Spots

5 Questions That Reveal Your Fire Safety Weak Spots -

The Importance of Test & Tag for Hotels, Restaurants & Cafes

The Importance of Test & Tag for Hotels, Restaurants & Cafes -

5 Checks to Know If Your Exit Lights Would Work During an Emergency

5 Checks to Know If Your Exit Lights Would Work During an Emergency -

How Professional Smoke Alarm Servicing Minimises Workplace Disruptions?

How Professional Smoke Alarm Servicing Minimises Workplace Disruptions? -

How Routine RCD Testing Prevents Downtime and Compliance Issues?

How Routine RCD Testing Prevents Downtime and Compliance Issues? -

The Role of Smoke-Alarm Systems for Business Continuity in Healthcare Facilities

The Role of Smoke-Alarm Systems for Business Continuity in Healthcare Facilities -

How Poorly Maintained Exit Lights Undermine Emergency Evacuation Efficiency?

How Poorly Maintained Exit Lights Undermine Emergency Evacuation Efficiency? -

How Expert Thermal Imaging Services Can Keep Businesses Running In Hostile Environments?

How Expert Thermal Imaging Services Can Keep Businesses Running In Hostile Environments? -

Stand-Alone Emergency Alarms: A Smart Investment in Business Continuity and Compliance

Stand-Alone Emergency Alarms: A Smart Investment in Business Continuity and Compliance -

Why Warehousing Leaders Choose Professional Smoke Alarm Systems?

Why Warehousing Leaders Choose Professional Smoke Alarm Systems?