Voltec Maintenance

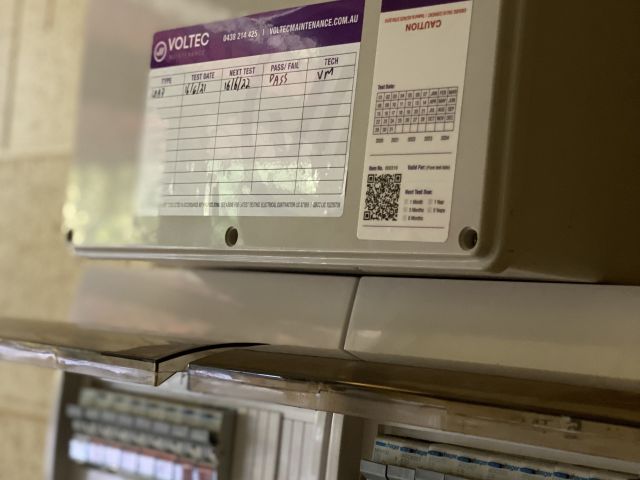

Voltec Maintenance is a preventative maintenance company based in Townsville, servicing Townsville, Charters Towers and Mt Isa. Our business focuses on Fire Protection and Test & Tag.

- Test and Tag Townsville (electric appliance testing)

- Emergency Exit Light Testing

- Fire Protection Testing

- RCD Testing

Voltec Maintenance

We pride ourselves on our data and reporting capability, for all jobs not just test and tag or appliance electrical testing. We guarantee our work, and all sites we leave are left in a compliant state ready for inspection. Unlike other Test and Tag businesses, we provide solutions, not problems. Having fully qualified electricians in Cairns and Townsville means that we can identify potential hazards in your workplace and rectify these faults during the electrical testing and appliance process. This means less disruption to your workplace, letting you focus on what you do best.

Voltec Maintenance places a large emphasis on the reporting of our information when conducting portable appliance testing services & test and tag. You can rest assured that once your site has been made compliant, we will follow up and send you your own data so you have records of your appliance electrical testing. There are no fun and games of keeping your test and tag data online like big franchises. We will even send you a reminder when it is time for your next electrical maintenance service or test and tag Townsville, so you don’t have to remember!

Looking for "test and tag near me?" You can learn more about portable appliance testing or our test and tag Townsville on our services page.

Electrical Testing Services, Electrical Maintenance

& Mobile Test and Tag Service

PAT Testing (Portable Appliance Testing) - Test and Tag Townsville

An electrical testing interval is determined by the environment that the appliance is normally exposed to. The more hostile the environment, the sooner PAT testing will be required. This is why it is important to have a qualified electrician conduct your appliance electrical testing. As a business, we pride ourselves on effectively communicating the standard required by law, and in turn helping the customer. We offer PAT testing with our mobile test and tag service.

PAT Testing

In recent times we have educated several businesses (who were getting all their test and tag done annually) to change their scope and have appliance testing completed at a five-yearly interval, saving them time and money on their test and tag, enabling them to use it elsewhere. We completed a mobile test and tag service for a client and found they could make that change. This specific business had a small workshop with 60 items that was subject to a lot of wear and tear. In doing this, the business was able to reduce the amount spent on test and tag in Townsville and get their risk areas tested more frequently to genuinely protect their employees.

Get an obligation-free quote for test and tag Townsville or just ask for free, expert advice. Contact us today.

RCD Testing Services - PAT Testing

This belief is equivalent to going to McDonalds and ordering a salad. It is doable, but it isn’t a realistic scenario. For the most part, RCD’s require Load or injection testing on an annual basis as there are lighting circuits that need to be properly tripped. As we are qualified electricians, we can perform an injection test and genuinely trip these circuits, ensuring the safety of you and your employees. Those large franchisees who would tell you this is not necessary, will simply push a button to test these circuits. Usually, they will not even distinguish if it genuinely is a power circuit, thereby putting it down to a lighting circuit, endangering the health and safety of your workplace and staff. This is why it is so important to have a qualified electrician perform your RCD testing services and PAT testing.

RCD Testing

At Voltec Maintenance we believe proper RCD, test and tag & portable appliance testing conducted on a regular basis is the backbone of your OH&S requirement. Determining that all your RCD’s are functioning properly on an interval-based time frame, will enable your business to have confidence in your ability to operate safely from an electrical standpoint. In the case that something did ever occur, you would have substantial proof of your efforts to provide a safe workplace for your employees. All our testing is kept down to the result for an individual CB from each DB and compared over time. By analysing this data, we can identify RCDs for replacement prior to them becoming a nuisance. The last thing you want is an RCD tripping on you and adversely affecting your ability to operate your business.

You no longer nead to look for test and tag near me! You can learn more about our RCD and other PAT testing services here or contact us for more information.

Combine your test and tag Townsville with Fire Protection and appliance testing

You may wonder why an electrical business in north Queensland also completes testing on Fire Extinguishers, Fire Hoses and Fire Blankets. The answer is simple, convenience for our clients. Examples of our multisite clients where they were organising several businesses to come into all their branches over North Queensland to perform the Fire Inspections, then they would have another guy coming in doing test and tag Townsville (appliance testing). Then finally they would have another guy come in and perform RCD testing and Emergency Exit Light testing.

Fire Testing

This whole ordeal would be a lengthy time-consuming process that would eat up their maintenance departments time and funds as each person who travelled to their sites would charge attendance fees. Furthermore, the quality of reporting would greatly differ from company to company and sometimes having to get a new business in would see completely different reporting which would make the actual OH&S situation seem unclear, thereby defeating the whole purposes of the testing. As we greatly care about our clients, and our boys spending more time seeing clients than their own families, we could not sit back and watch them struggle. We decided to become a One-Stop Shop for all your fire protection testing, RCD testing, Emergency Exit Light testing and test and tag Townsville needs!

Do you need PAT testing or electrical maintenance completed? Contact us on (07) 4426 1919 today for an obligation-free quote or for free expert advice.

Why choose Voltec Maintenance for your PAT testing or test and tag Townsville?

On top of this interval-based testing (which we take full ownership of), we will email you 4 weeks prior to testing with a calendar invitation to remind you to rebook with us. This allows for a seamless approach, to ensure your testing is conducted on time. We also take full ownership of faults and any required rectification. It would be true to say that there are several companies out there who attempt to provide the services of Fire Equipment testing, Test and Tag Townsville, Exit Light Testing and RCD Testing. However, there are not many companies out there who offer all these services across north Queensland, combined with the full fault rectification service like us.

Your all-round electrical maintenance electrician

Whether it’s an RCD that needs replacement, or an exit light that needs to be completely switched out, we will take care of this for you. In most cases, immediately that day, on site. This service takes the job of you having to reach out to yet another company to come in and quote, then find a time and organise this service. Which is what you will have to do with a large national franchise. Our electrical testing services not only provide convenience for our customers, but also peace of mind that the job will be completed at a high-quality standard.

If you are looking to take your OH&S requirements to the next level and would like your business properly looked after by locals (who live and breathe safety in the workplace), then look no further! We are here to support you for all your electrical testing service needs. We look forward to meeting you and your team.

To learn more about our PAT testing and other electrical testing services, contact us today.

Get a Free Quote

For electrical maintenance and compliance services

Do you want to learn more about our services and how Voltec Maintenance can help you? Call us today to get free expert advice or a no-obligation quote.